The processing technique may form the bright mirror-like nickel-phosphorus alloy plating layer on the surface of materials, such as steel, cast iron, aluminum alloy and copper alloy, with high abrasion performance & corrosion resistance, excellent bonding strength of plating layer, and uniform thickness. The processing technique of this division may form the bright mirror-like nickel-phosphorus alloy plating layer on the surface of materials, such as steel, cast iron, aluminum alloy and copper alloy, with rigidity of HV1000 (equivalent to HRC69), high abrasion performance & corrosion resistance, excellent bonding strength of plating layer, and uniform thickness. The plating speed is very fast, up to 20um/h.

Detail

Electroless nickel technique

Electroless nickel technique

The processing technique may form the bright mirror-like nickel-phosphorus alloy plating layer on the surface of materials, such as steel, cast iron, aluminum alloy and copper alloy, with high abrasion performance & corrosion resistance, excellent bonding strength of plating layer, and uniform thickness.

The processing technique of this division may form the bright mirror-like nickel-phosphorus alloy plating layer on the surface of materials, such as steel, cast iron, aluminum alloy and copper alloy, with rigidity of HV1000 (equivalent to HRC69), high abrasion performance & corrosion resistance, excellent bonding strength of plating layer, and uniform thickness. The plating speed is very fast, up to 20um/h.

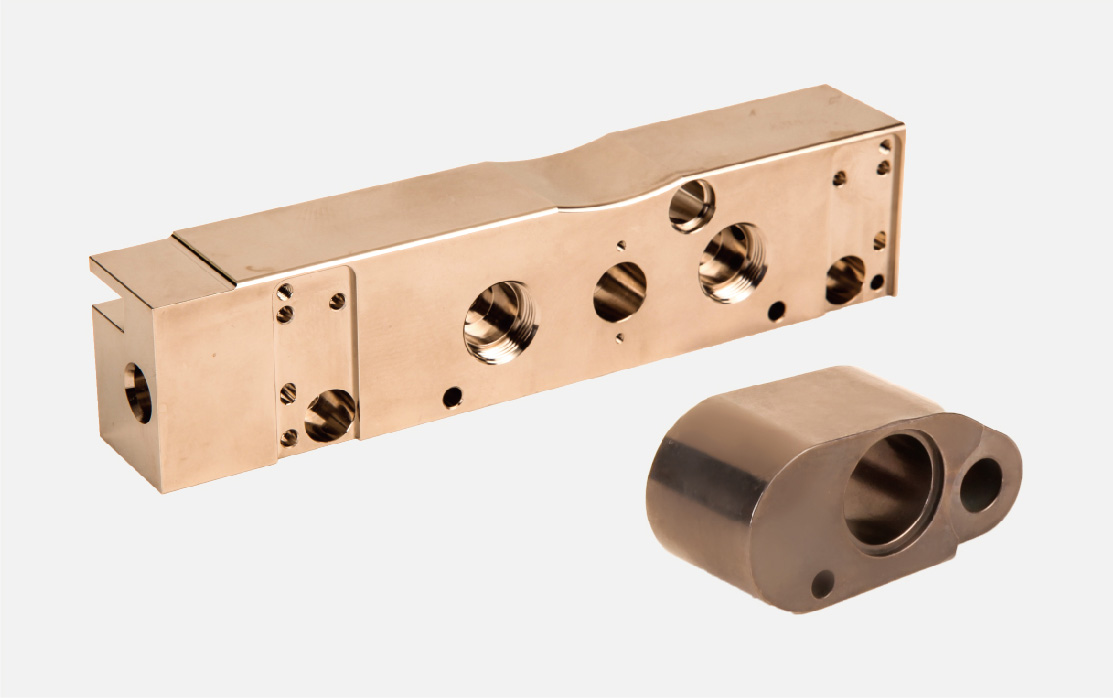

Display of electroless nickel products

Process features: Have high adaptation, and achieve uniform plating layer on the internal surface of blind holes, deep holes, pipe fittings, corners and gaps

Process features: Have high adaptation, and achieve uniform plating layer on the internal surface of blind holes, deep holes, pipe fittings, corners and gapsPrevious: Surface treatment for auto parts

Next: gold plating